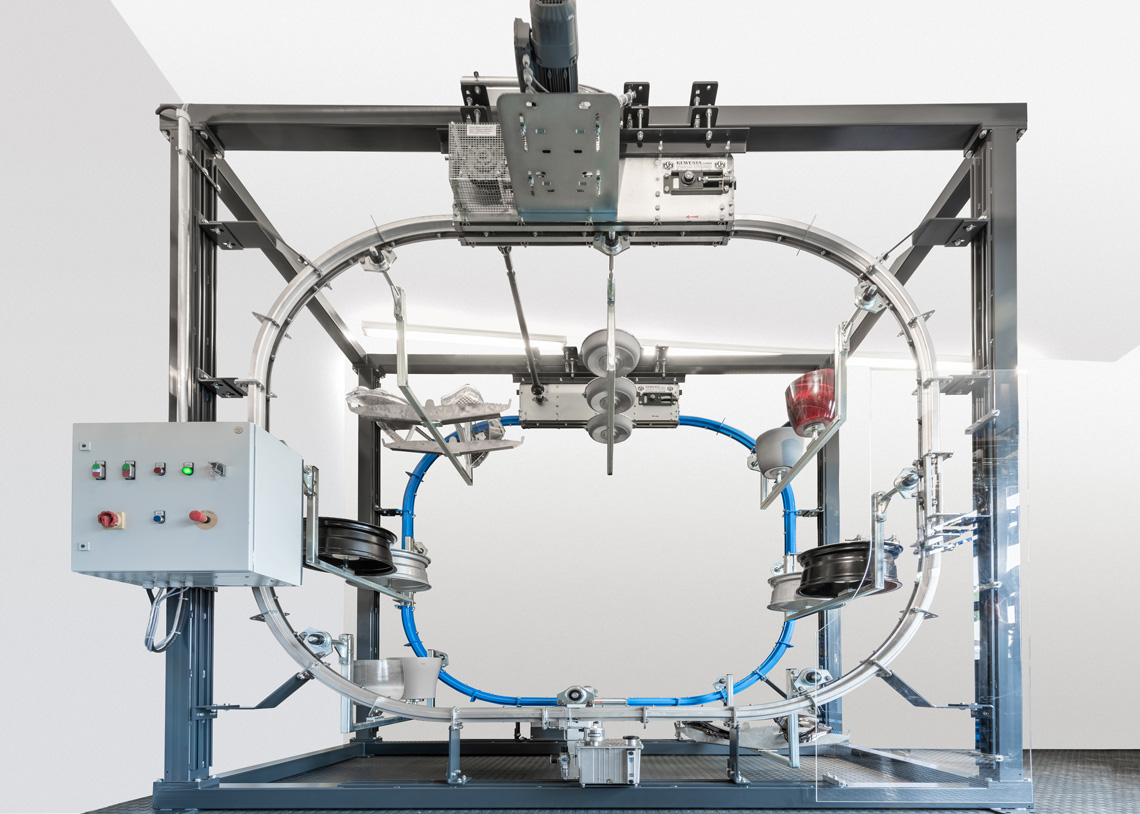

Gondola Conveyor

The chain principle has been used in so-called paternosters for quite some time to vertically transport gondolas. Kewesta has decided to go one step further:

With its sophisticated universal joint chains, intricate three-dimensional systems are conceivable, on top of those that transport gondolas up and down in an upright pattern.

Since the universal joint chain cannot unfold in the conveyor rail, it is far more superior to the normal cardan joint chain on inclines.

It can make full use of this advantage, especially in vertical inclines.

This results in the possibility of approaching several levels on top of each other, without having to work with expensive and maintenance-intensive deflection wheels.

Particularly in surface installations, compact and energy-efficient systems can be built, allowing for seamless vertical movement from a lower processing level into dryers and ovens.

A potential cooling level with natural heat exchange can integrate perfectly just below.

Naturally, these conveyors can also be combined with robots or other conveyors from the Kewesta programme.

The lightweight yet robust Kewesta chains not only ensure high reliability, but also provide cost-effective and energy-efficient solutions.

+49 (0) 6183 91680

+49 (0) 6183 91680